Increasing Safety with Effective Crossarms Extensions by Rauckman

Temporary crossarm extensions, also commonly known as Hot Arms or Extension Arms are an important hotline tool which aid in temporarily holding conductors while utility line workers perform conductor line or insulator maintenance on a crossarm. They allow line workers to avoid cutting off power to the end user during maintenance. Hot Arms are also valuable hotline tools that can be used for moving conductors away from a work area, such as during road widening.

What to Look for When Choosing Hot Arms

When choosing Hot Arms that are ideal for replacing or working on dead-end crossarms, ensure their composition of electrical-grade fiberglass and foam, can safely withstand the rigorous electrical environment they are exposed to when used with live line. To ensure that your temporary crossarms offer exceptional resilience and durability, it is important to make sure they meet ASTM F711 standards.

Hot Arm Durability

Temporary crossarm extensions should meet ASTM F-711 standards. This standard applies specifically to the durability and safety of the fiberglass reinforced plastic rod portion of the arm during the manufacturing process. Durable temporary crossarms are typically constructed using electrical-grade fiberglass reinforced thermoset resins surrounding a uni-cell foam core.

Which Safety Standards Apply to Hot Arms?

Safety for lineworkers is paramount in the development of Hot Arms. Hot Arms should meet ASTM F-711 standards, which shapes the technical attributes for fiberglass-reinforced rods intended for use in live line tools.

Two common questions regarding hot arms are whether they are required to meet ASTM F-3121 or OSHA 1910.269 standards. ASTM F-3121 is for use of hand-held live line insulating tools for in-field care, use, and testing guidelines. This only applies to the fiberglass stick.OSHA regulations cover Personal Protective Equipment (PPE); however, Hot Arms, not classified as PPE, would not fall under the umbrella of OSHA 1910.269 standards.

Customization of Hot Arms

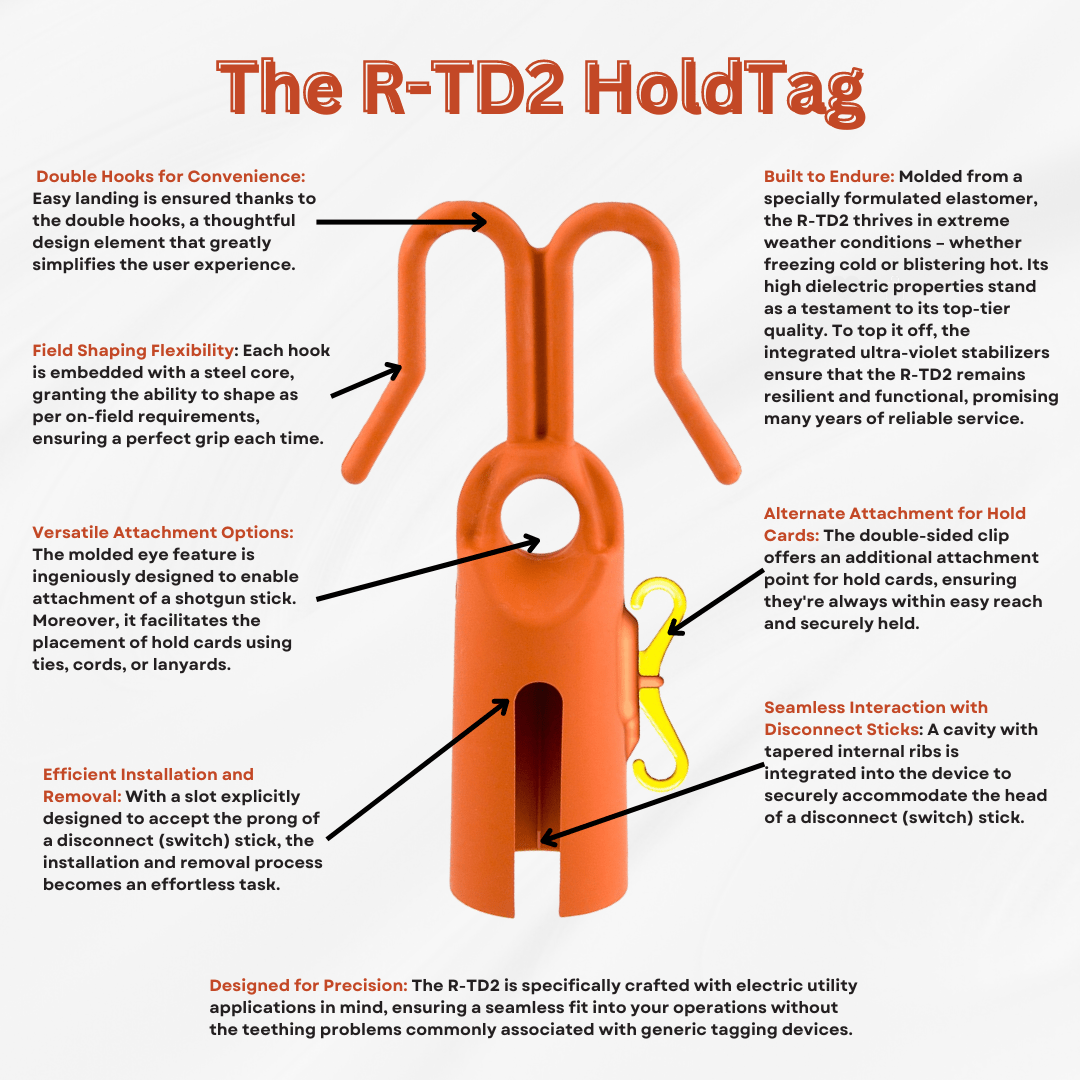

Choosing a manufacturer that offers customization for your temporary crossarms ensures you are covered for specific field tasks. Hot Arm extensions can be customized with a variety of attachments to meet your specific requirements. Whether you are changing insulators, installing or replacing hardware, or stringing new conductors, choosing a supplier that offers versatility in attachments allows you to work safely in various situations.

Hot Arms can be customized using an extensive selection of hotline tool products and attachments. Attachments to the Hot Arm itself include Hot Arm Wireholders, with a generous 1” opening to accept conductors up to 795 ACSR, and Wireholder insulators. Insulators allow for Hot Arms to be used on circuits up to 34.5 kV, rather than the typical 15 kV circuits. In inclement weather or if the arms are left out overnight, adding insulators on the Wireholders is recommended.

Choose Rauckman for Reliable Hotline Tools

Rauckman is a leading manufacturer for electrical utility companies, and we would love to be your product partner. For more information on our Hot Arms, click here. To get in contact with a Rauckman expert, visit our contact page and fill out the form. One of us will get in touch with you shortly.