The Essential Role of Switching Disconnect Hot Sticks in Utilities

Safety remains the top priority when it comes to utility work. For decades, utility workers have relied on specialized electrical safety tools to ensure safety while working on live power lines. Among these indispensable tools are switching disconnect hot sticks, also known as electrical disconnect sticks. These have been essential since the early 1900s, and now, with modern technology and effective fiberglass design from Rauckman Utility Products, they are more efficient and safe now than ever.

Evolution of Safety with Switching Disconnect Hot Sticks

Switching disconnect hot sticks have evolved just like other advancements in utility infrastructure. They were originally crafted from wood, being rudimentary yet effective. As technology progressed and safety standards became more stringent, the need for more robust materials led to the adoption of fiberglass-reinforced thermoset resins.

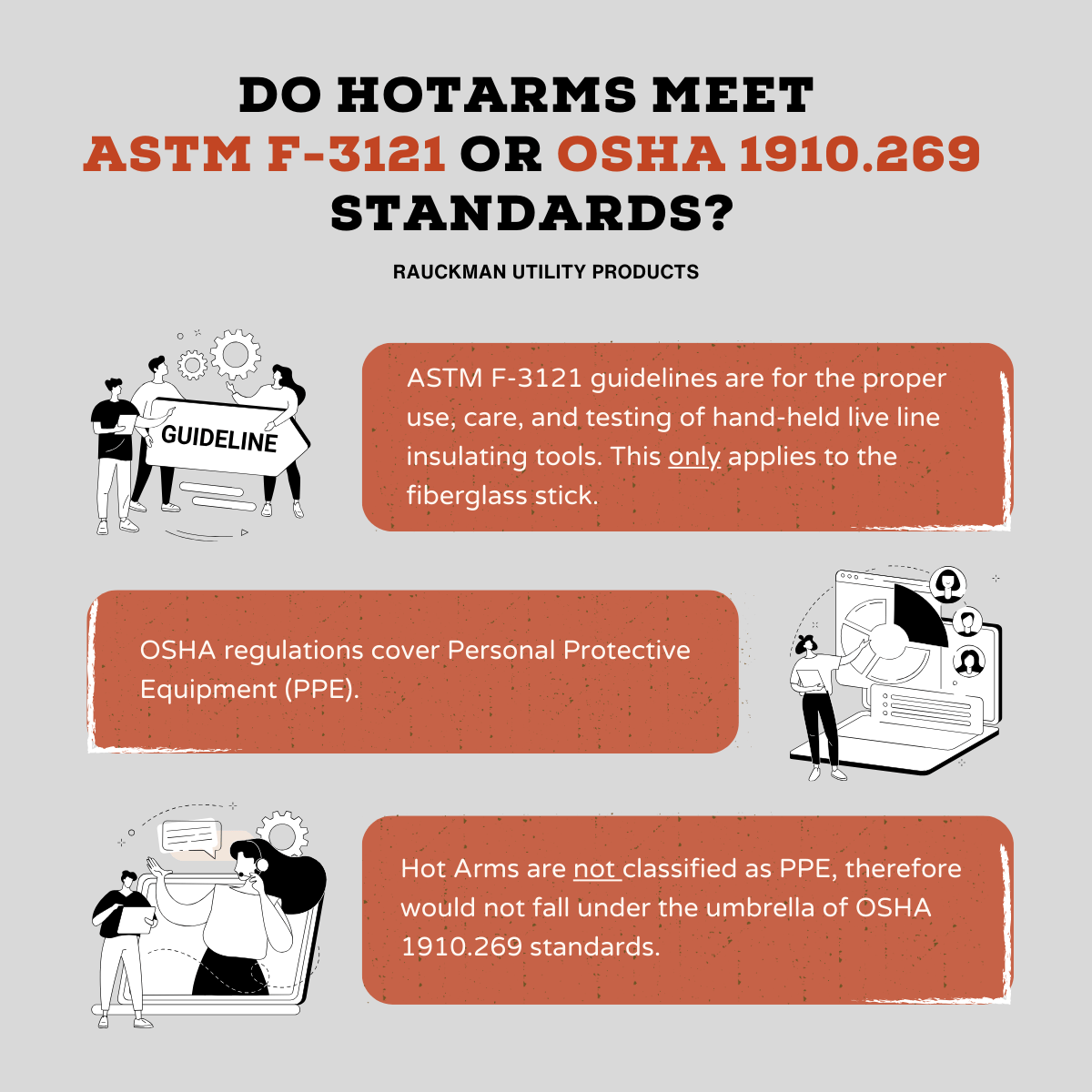

Today, these insulated hot sticks are manufactured to meet or exceed ASTM F711 safety standards, they provide a crucial barrier between workers and the hazards of live lines. Rauckman Utility Products, a leader in utility safety equipment, takes pride in engineering utility lineman tools that prioritize both safety and durability.

Versatility and Functionality

High voltage hot sticks are needed for operating overhead and underground apparatus, including cutouts and switches. Rauckman offers a range of options to cater to diverse utility needs. They are available in two diameters: 1 1/4″ and 1 1/2″. These hot sticks also come with a vast selection of different head styles to suit various applications.

The “Switch Stick” style features a notch designed to fit the trunnion of a cutout fuse tube, facilitating seamless engagement during fuse tube replacement. The “Disconnect” style offers versatility for different operational requirements. With several options for lengths and model numbers, utility workers can find the perfect fit for their specific tasks.

Commitment to Safety

At Rauckman Utility Products, safety is a commitment. Our hot sticks are deliberately engineered with closed-cell foam-filled fiberglass handles to ensure ergonomic comfort and maximum insulation. By utilizing premium materials and adhering to stringent safety standards, Rauckman hot sticks provide peace of mind to utility workers operating in challenging environments.

Request a Quote

Rauckman Utility Products high voltage disconnect tools are made in the USA and empower utility workers to perform their duties with confidence. As technology advances and safety standards evolve, it’s important to ensure that utility workers have the tools they need to stay safe on the line.

To request a quote or get more information from one of our representatives, please fill out our contact form and we will be in touch.