The ZAPshield Active Animal Deterrent

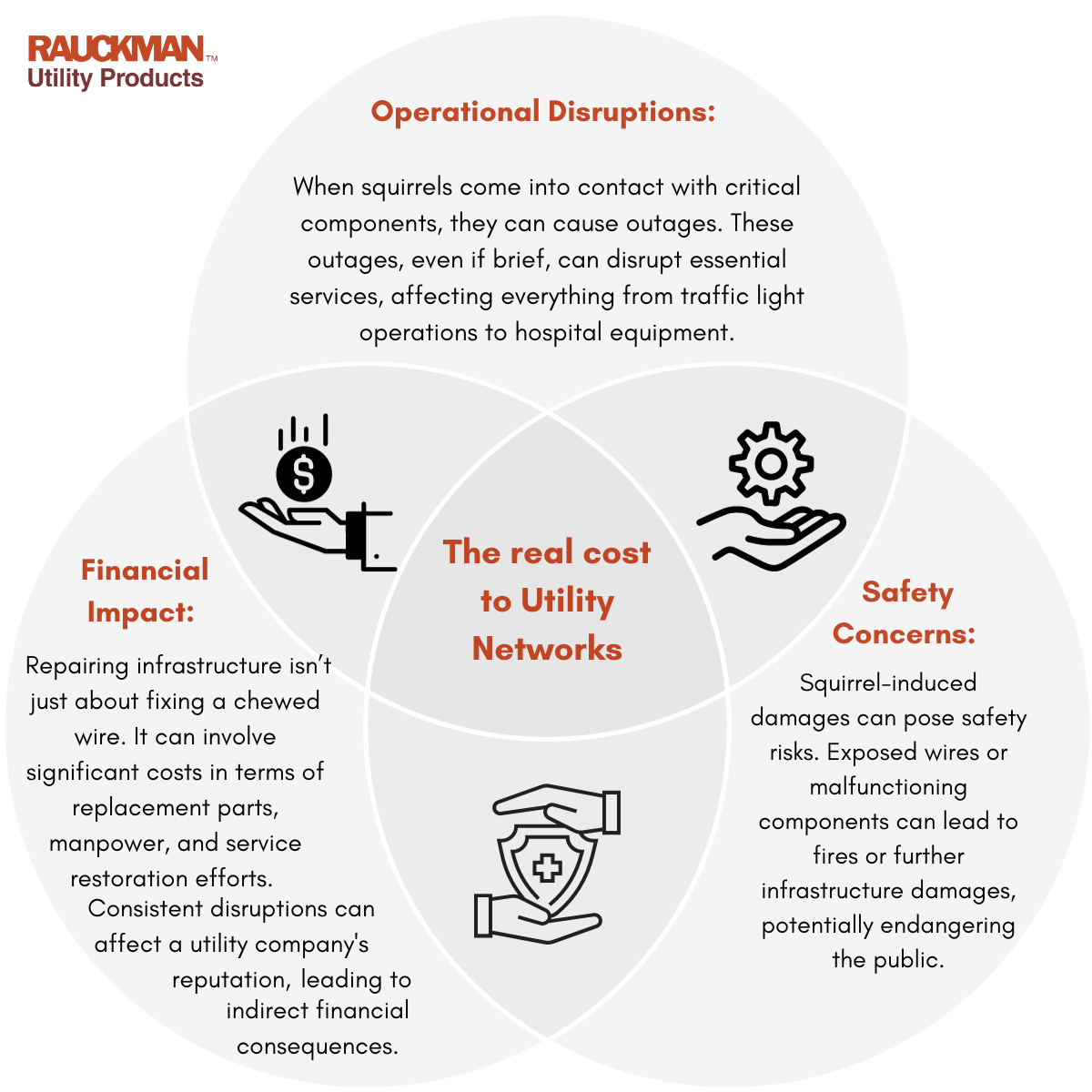

Animal-related interruptions in utility infrastructure can lead to outages, significant financial losses, and potential harm to the animals themselves, which is why animal mitigation is crucial to maintain an uninterrupted flow of electricity. At Rauckman Utility Products, we understand these challenges and have developed an innovative solution to address them: the ZAPshield. This blog explores how the unique Rauck-Shock technology not only deters animals but also conditions them to avoid electrical equipment in the future.

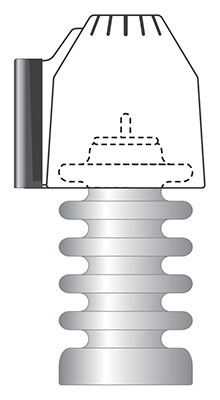

What is the ZAPshield?

The ZAPshield is a UV-stable animal shield in Rauckman’s animal mitigation line, specifically designed for transformer bushing protection. Using the patent-pending Rauck-Shock technology, the ZAPshield delivers a non-lethal electrostatic discharge when animals come into contact with it. This gentle jolt is sufficient to deter them without causing harm, ensuring both the safety of the animals and the smooth operation of electrical equipment.

How Rauck-Shock Technology Works

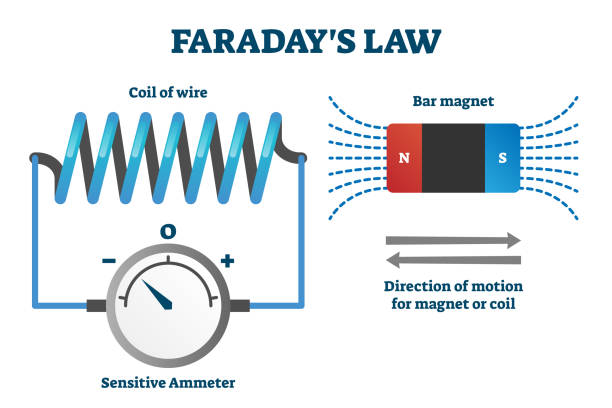

Rauck-Shock technology is based on the principles of Faraday’s law of induction, ensuring a safe and effective, non-lethal animal deterrent. When an animal touches the ZAPshield, it experiences a mild, non-lethal shock. This shock is designed to be memorable but not painful, which creates a negative association with the electrical equipment. Over time, animals learn to avoid these areas altogether, effectively reducing the risk of future interruptions.

Faraday’s law of induction vector illustration.

The Training Effect

One of the standout features of the ZAPshield is its ability to train animals to stay away from electrical equipment. Unlike other deterrent methods that might require repeated applications or can be harmful, the ZAPshield’s gentle shocks condition animals in as little as one unforgettable experience. This conditioning process is critical because it reduces the likelihood of animals returning and causing disruptions. The ZAPshield doesn’t just deter, it educates.

Benefits Beyond Deterrence

Bushings on electrical distribution equipment are notoriously prone to interference from animals such as squirrels, snakes, and birds. This interference can cause outages, costing power utilities millions of dollars in system repairs and significantly diminishing customer goodwill due to reduced system reliability. The ZAPshield is an effective snake and bird deterrent, as well as a great squirrel deterrent system by using Rauck-Shock polymer panels that pick up a charge from the bushing and deliver a non-lethal electrostatic discharge when contacted by an animal. This approach not only protects the equipment but also ensures that animals are safely deterred without harm.

<iframe width=”560″ height=”315″ src=”https://www.youtube.com/embed/dR14Bmm0SkY?si=W0MFF2AEcksGYi-g” title=”YouTube video player” frameborder=”0″ allow=”accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture; web-share” referrerpolicy=”strict-origin-when-cross-origin” allowfullscreen></iframe>

Utility Pole Protection for Safety and Performance

Rauckman Utility Products offers several passive options to better protect exposed bushings on electrical distribution equipment, including transformers and substation apparatus, from inadvertent electrical contact with animals. All Rauckman wildlife mitigation products possess enhanced UV stability, including hindered amine light stabilization. They are track-resistant and flame-retardant per the V0 criteria of the UL94 standard. This means that the Rauckman wildlife mitigations products will self-extinguish a flame in 10 seconds or less and will not drip flaming particles, which could cause a fire.

ZAPshield Installation

A significant advantage of the ZAPshield is its hassle-free installation process. Designed to minimize downtime, the ZAPshield can be installed ‘hot’. By eliminating the need to power down or disrupt service, live line installation is much more efficient for utilities.

Reach Out for Your Customized Animal Protection Plan

For electrical infrastructure safety and wildlife protection for utilities, the patent-pending animal barrier, ZAPshield and Rauck-Shock technology represent the pinnacle of animal mitigation solutions. By training animals to stay away from electrical equipment, we help utilities prevent costly outages and protect wildlife.

For more information on our products and how they can help you ensure utility equipment reliability while protecting wildlife, contact us today.