Conduit Riser Cover for Wildlife Protection

Proper wildlife protection in electric utilities has historically been a challenge. The need for robust wildlife protection devices has never been more critical. The CRC-100L by Rauckman is the best in conduit riser safety solutions. It improves the reliability and safety of electrical equipment and is a comprehensive solution to mitigate risks and ensure uninterrupted service delivery.

Conduit Riser Cover Features

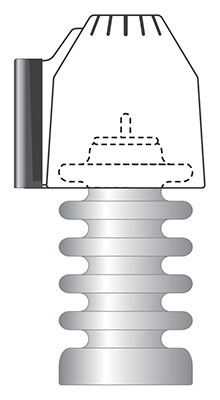

The Conduit Riser Cover is specifically designed for wildlife protection. Its unique features, including Flexible Fingers for a proper fit and track-resistant silicone construction, make it an ideal choice for safeguarding conduit risers from animal interference and debris accumulation.

The Conduit Riser Cover’s track-resistant silicone composition is engineered to withstand the rigorous conditions and demands of the industry. This silicone is specially formulated for the electric utility sector, ensuring durability and longevity, even in environmental challenges.

This product is also a high UV stability electrical cover which is reinforced by Hindered Amine Light Stabilization (HALS). This ensures reliability and performance under prolonged exposure to sunlight. The Conduit Riser Cover helps you to maintain system integrity and longevity.

Easy Install Conduit Riser Protection

Installing the Conduit Riser Cover is easy thanks to its user-friendly design and Locking Slide Closure mechanism. Electric utility professionals can quickly and easily secure the covers in place, minimizing downtime and ensuring efficient deployment of wildlife protection measures.

Conduit Riser Cover for Wildlife Protection

When it comes to electric utility wildlife protection devices, the Conduit Riser Cover offers the most versatility and reliability. Whether you are safeguarding conduit risers or larger bushings, this product gives you peace of mind and ensures the safety and reliability of critical infrastructure.

Invest in the Conduit Riser Cover today to safeguard your infrastructure against wildlife and debris. For further information or to request a quote please reach out to us or contact one of our representatives.