Why Understanding Plastics is Essential for Wildlife Mitigation

You can better assess the wildlife protection products being used on your network if you take the time to learn about the different types of plastics used to create this type of equipment and their characteristics. Having knowledge of the fundamentals of plastic manufacturing and additives gives you important insights for successful wildlife mitigation, as the same testing methods that apply to electrical equipment do not always apply to plastic wildlife covers. Additionally, depending on how the plastic is made, knowing more about the material can help you determine costs, particularly when buying in bulk.

Types of Plastics Used in Wildlife Mitigation

Plastics are divided into thermoplastics, which can be melted and reshaped, and thermosets, which remain solid once cured. Though all plastics are polymers, not all polymers are plastics.

Plastics used in wildlife mitigation must meet specific durability, weather resistance, and electrical insulation requirements. Each of these plastics are chosen for specific applications in wildlife mitigation devices based on their unique properties.

Here are the main types of plastics with comments on use in wildlife mitigation:

Polyethylene Terephthalate (PET)

While used extensively in consumer products, PET is typically not used in wildlife protection applications.

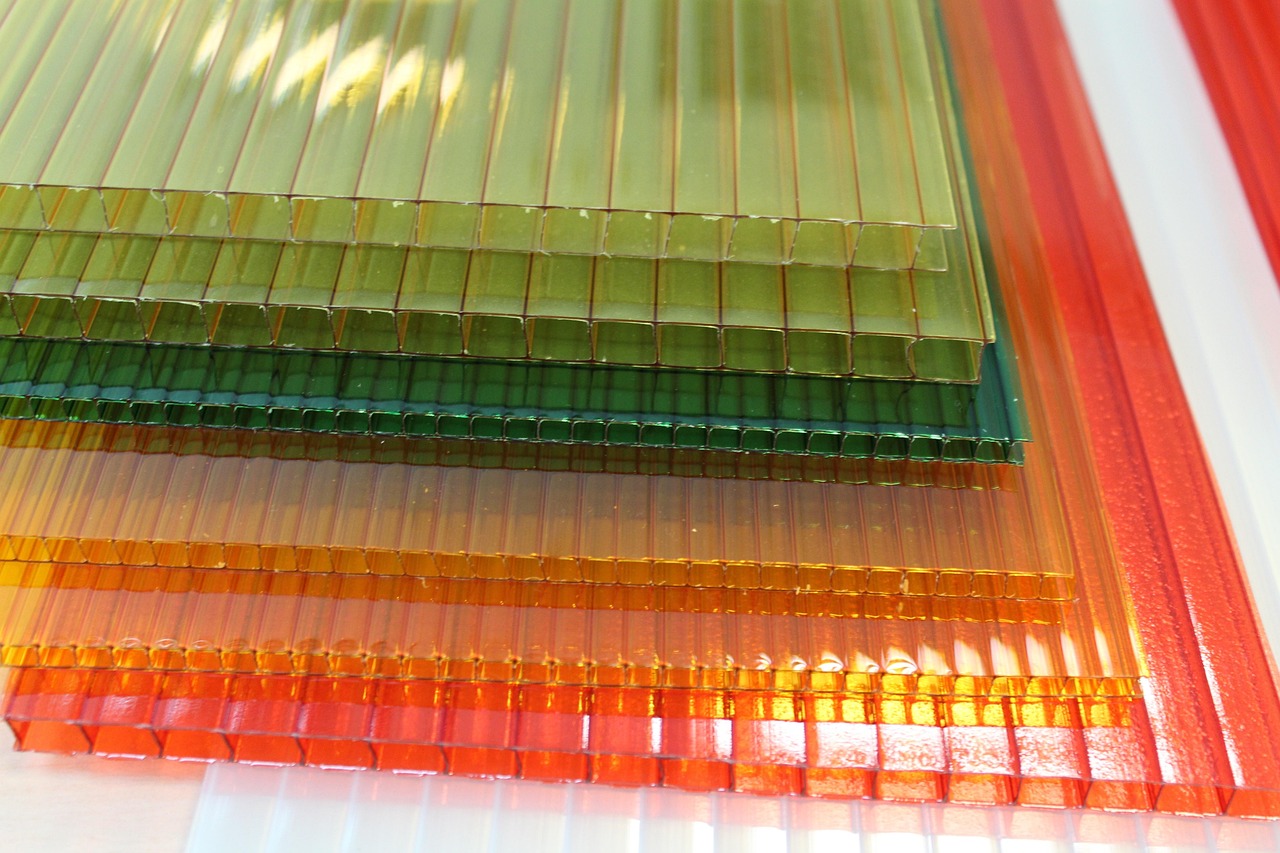

Polycarbonate (PC)

- High impact resistance,

- Durability

- Transparency

- UV-stable

- Can withstand extreme temperatures

Ideal for bird diverters, insulator covers, and animal guards.

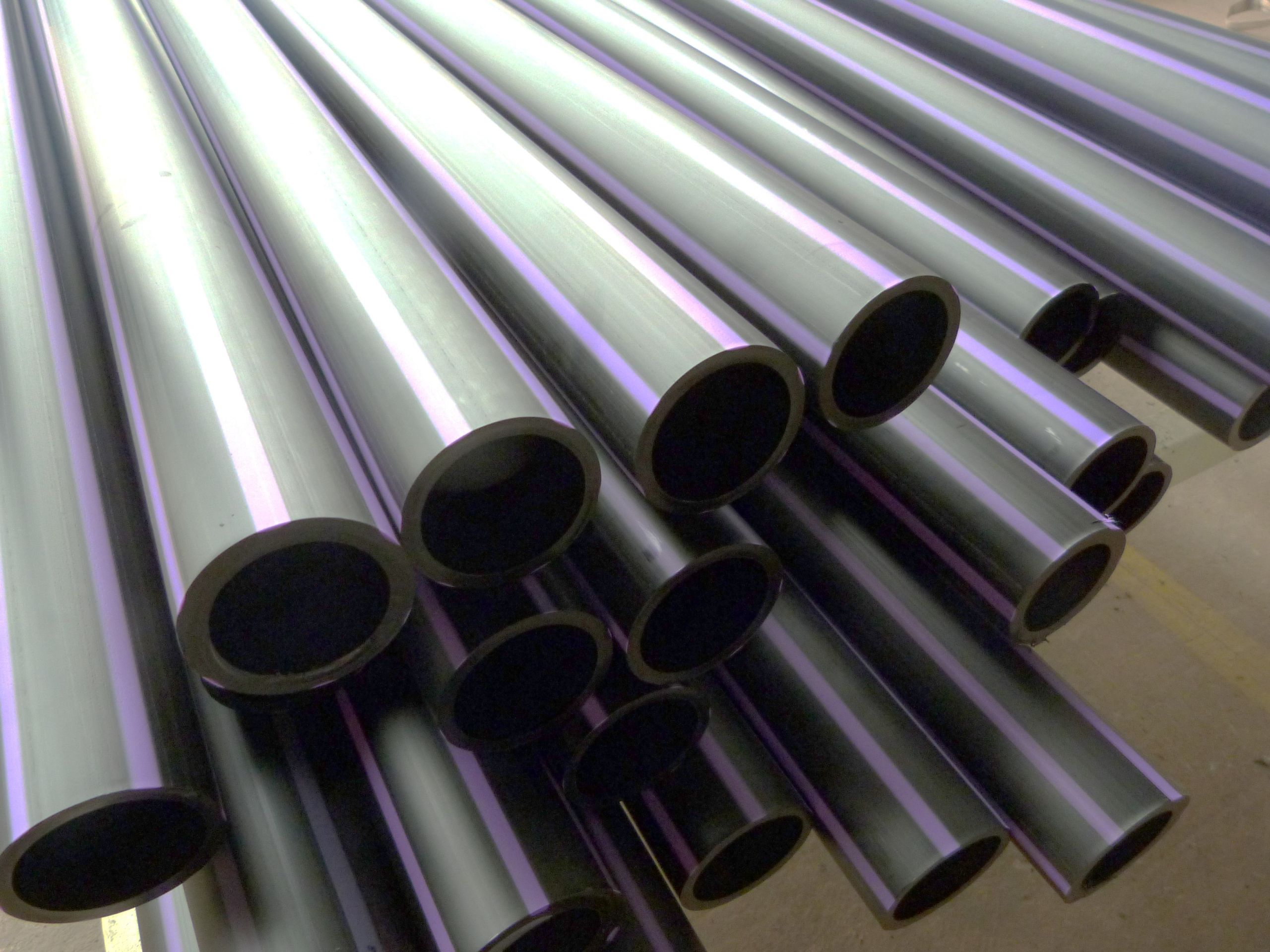

Polyvinyl Chloride (PVC)

- Affordable

- Highly resistant to chemical and environmental degradation.

- Flexible

- Flame-retardant

- Weather-resistant

Commonly used for insulated coverings, conduits, and protective barriers for wires and cables.

Polyvinyl Chloride Plastic Tubes

Polypropylene (PP)

- UV resistant

- Lightweight

- Chemical-resistant

- Electrically insulating

Commonly used for protective coverings, wraps, and wildlife guards.

Polypropylene Plastic pellets.

High-Density Polyethylene (HDPE)

- High impact strength

- Weather resistance

- Low moisture absorption.

- Difficult to recycle

Commonly used for wildlife barriers, insulator covers, and conductor guards.

These are the main plastics used for wildlife mitigation devices, however, others, such as silicone rubber and polyamide are also used for certain components in this type of equipment.

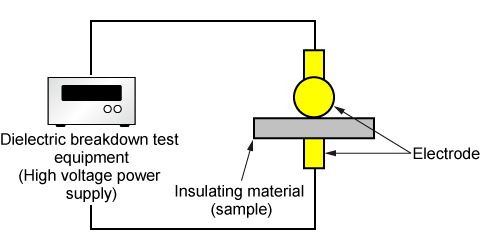

What You Need to Know About Testing Plastic Materials

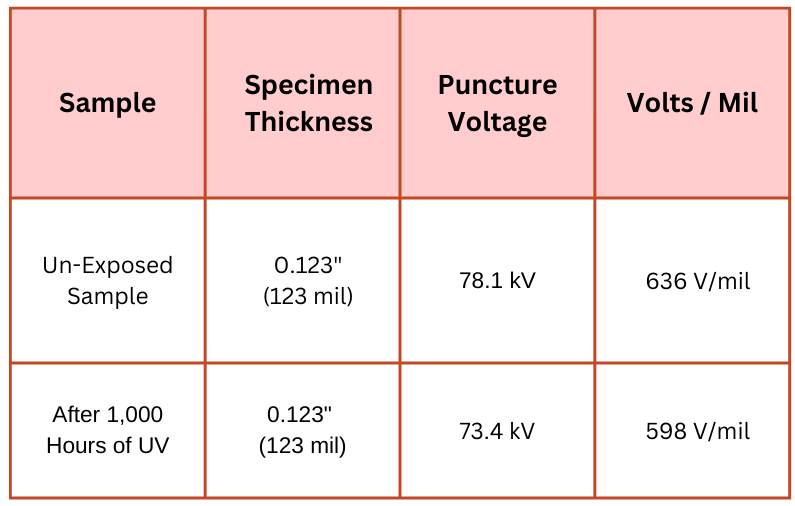

Testing and data sheets are essential for understanding material behavior under different conditions, especially weathering. There are several essential tests to ensure the safety and longevity of plastic used for wildlife mitigation, however one of the most important tests to conduct is flammability testing.

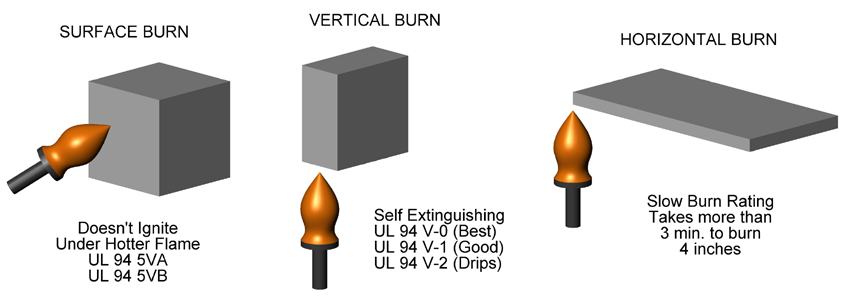

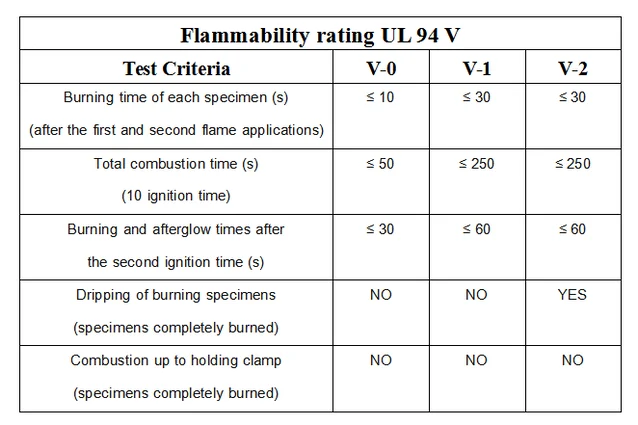

The UL 94 guideline outlines different testing methods and criteria for flammability tests and the resulting rating of certain plastics. Specifically for wildlife mitigation, a V-0 rating is the gold standard when it comes to flammability testing. This means the material stops burning within 10 seconds after being exposed to flame and does not produce flaming drips, making it highly resistant to ignition and reducing the risk of wildfires or damage caused by wildlife-related incidents.

Standardizing vs. Whole Product Testing

Standardized tests for plastics are essential for understanding baseline properties. Evaluating the material properties eliminates variables and gives you the confidence to make informed decisions about product performance. For example, UV-resistance is better tested on a coupon-sized material sample rather than the entire product because it is nearly impossible to evenly expose the entire piece of equipment to consistent and predictable UV radiation. However, for application testing such as wind-resistance and cold weather instability, whole-product testing would be better as it will help ensure the product performs as intended in real-world conditions.